07 3219 0133

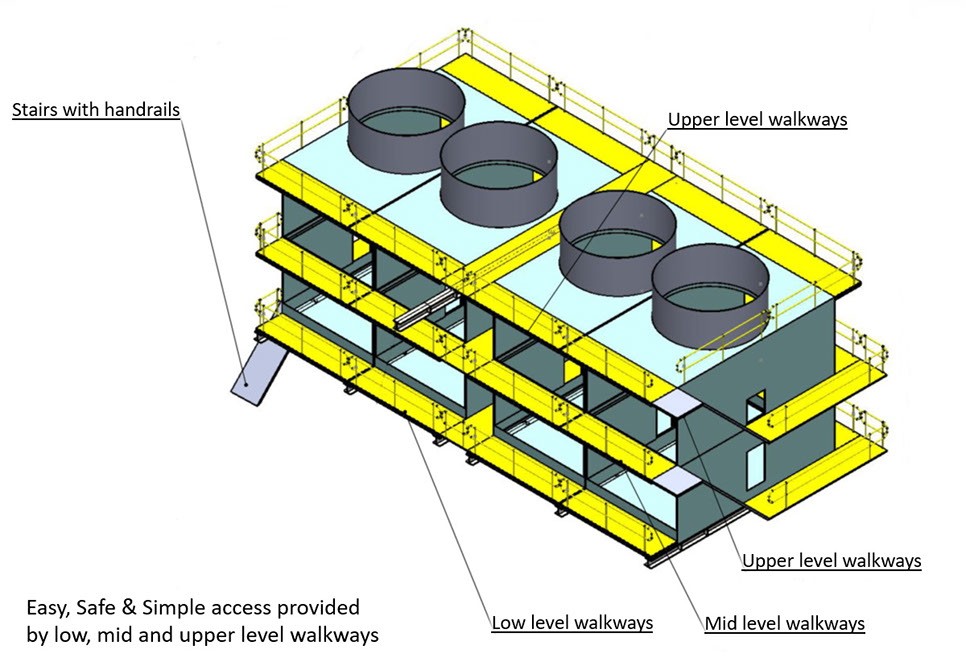

Walkways, Stairs and Ladders

Easy, Safe and Simple access solutions for cleaning, inspection and maintenance of cooling towers

Access for Maintenance

Upper Level Walkways

Mid Level Walkways

Stairways and Handrails

High Level Walkways

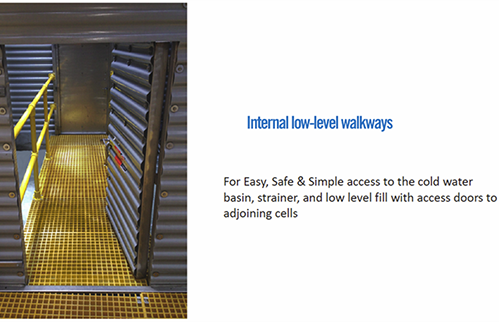

Low Level Walkways

Interactive Diagram - Explore Applications

Access platforms and walkways are fabricated from strong, corrosion resistant pultruded composite components and FRP moulded mesh which are generous 1200mm minimum width. Platforms enable service teams with tools and equipment - Easy, Safe and Simple access.

Pritchard walkways and steps are constructed using FRP moulded gratings that are;

- Fire resistance

- Corrosion resistance

- Lightweight, but strong

- Long service life and maintenance free

- Non-conductive

- Easy, safe and simple installation

- Non sparking

Pritchard rigid composite structural profiles are manufactured using the pultrusion process.

Pritchard uses vinyl ester resin, providing superior quality over other resins including polyester resins providing the following benefits;

- Fire resistance

- Corrosion resistance

- Lightweight, but strong

- Long service life and maintenance free

- Non-conductive

- Easy, safe and simple installation

- Non sparking

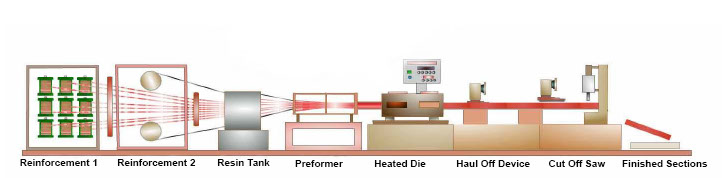

The Pultrusion Process

Pultrusion is a continuous process of pulling resins and reinforcing materials through a heated die, forming profiles of uniform cross section in a continuous length.

The pultrusion process involves:

Reinforcement 1 - Unidirectional roving, the reinforcing fibre that runs along the length of the profile.

Reinforcement 2 - The fibre mat is added in which is a multi-directional reinforcement.

The resin, typically vinyl ester for increased durability and strength.

The fibre is fully wetted with the liquid resin and pulled into a preformer for aligning the reinforcements.

Then into the heated die where curing takes place.

Once the material enters the die, a surface veil may be added which enhances the final product's surface appearance.

All the resins used in the pultrusion process have a catalyst or hardener added when the resin is mixed which is activated at about 93°C. Consequently, as the wet reinforcement passes through the heated die, the product changes from liquid to a solid profile with all the reinforcement laminated within.

The product is the pulled through the die by "the puller ". The final product is then cut to the desired length.

TOP

Representing

Baltimore Aircoil

The Future of Cooling Tower Technology

Pritchard Pacific Pty Ltd (A.B.N. 52 118 797 989)

6 Curban Street, Underwood QLD 4119

Phone 07 3219 0133, Fax 07 3341 9666

Email: mail@pritchard.com.au

Cooling Technology Institute

Proud Member